Popular on TelAve

- OddsTrader Asks: What Are the Chances Your Team Makes the NFL Playoffs? - 791

- Zoiko Orbit Launches: Seamless Global Travel Connectivity in 200+ Countries, Including Africa - 577

- EMBER™, the Only Standardized System Linking Workforce Identity to Growth, Appoints Global Brand Visionary Bret Sanford-Chung to Board of Directors - 367

- Modernizing Pole Data Collection for Next-Gen Network Expansion - 353

- Phinge®, Home of Netverse® and Netaverse™ With Verified and Safer AI Announces "Test the Waters" Campaign for Potential Regulation A+ Offering - 352

- FreeTo.Chat Launches Silent Confessions, the Best Confession Site for Anonymous, Ad-Free Truth Sharing - 345

- Sober.Buzz Adds Second Podcast, "Spreading the Good BUZZ" Guest List Grows, Numbers Continue Growing Globally, All While Josh and Heidi Tied the Knot - 341

- Iterators Named Preferred Accessibility Testing Vendor by MIT - 340

- Assent Joins AWS ISV Accelerate Program - 334

- Contracting Resources Group Appears Again on the Inc. List of Fastest-Growing Companies - 332

Similar on TelAve

- "Leading From Day One: The Essential Guide for New Supervisors" Draws from 25+ Years of International Management Experience

- John Thomas calls for unity and prayer after tragic loss

- CCHR: For Prevention, Families Deserve Truth From NIH Study on Psychiatric Drugs

- Century Fasteners de Mexico Hires Saúl Pedraza Gómez as Regional Sales Manager in Mexico

- Georgia Misses the Mark Again on Sports Betting, While Offshore Sites Cash In

- Century Fasteners de Mexico Awarded AS9120B and ISO9001:2015 Quality Certifications

- $5 - $20 Million in Sales for 2026; $25 - $40 Million for 2027 Projected with NASA Agreements; New MOU Signed to Improve Solar Tech in Space

- BeeCool Bikes Unveils Next-Generation "Super Frame" with Bee Defender Series

- Century Fasteners Corp. Exhibiting at the 2025 International Fastener Expo

- The Squires Group Becomes a Workday Partner

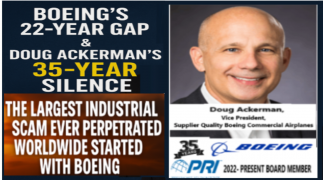

Boeing's 22-Year Certification Gap & Doug Ackerman's Boeing VP Of Quality 35-Year Silence: A Quality Oversight Crisis Exposed

TelAve News/10873197

World recognized QA Expert and Boeing Shareholder DARYL GUBERMAN Unveils Risks from Supplier Mismanagement and NADCAP Conflicts

EVERETT, Wash. - TelAve -- Boeing's quality oversight has come under renewed scrutiny as a 22-year gap in AS9100 certification coincided with key leadership roles held by Doug Ackerman, a 35-year company veteran. From 2020 to 2024, Ackerman served as Vice President of Supplier Quality, a period in which still Boeing required its suppliers to be AS9100 certified—yet was not certified itself. During this time, Ackerman remained silent on this glaring contradiction, raising questions about internal accountability and external compliance. Ackerman also holds a seat on the Performance Review Institute (PRI) board 2020–Present, responsible for overseeing NADCAP certifications—further entangling Boeing in a network of overlapping interests.

While Doug Ackerman Oversaw the 777 Program: Quality Issues & Whistleblower Testimony

On April 17, 2024, whistleblower Sam Salehpour testified before the U.S. Senate regarding alarming quality problems on Boeing's 777 program, where Ackerman was involved from 2002–2022. Salehpour described forced-fit assemblies leaving structural gaps that could lead to midair failure, production shortcuts jeopardizing long-term airframe integrity, and systemic pressure to overlook defects in pursuit of production targets.World recognized QA Expert and Boeing Shareholder DARYL GUBERMAN attended the DHS Subcommittee Whistleblower Meeting concerning Boeing's deeply concerning quality practices https://www.newstribune.com/photos/2024/apr/18/3749044/.

Table 1 — Boeing's Conflict of Interest at a Glance

Reason Why:

A) Nineteen days after 911 Boeing came out with a notification to lay off 20,000 to 30,000 employees.

1) April 2002 Supplier Bulletin Performance Review Institute NADCAP National Aerospace and Defense Contractors Accreditation Program certification (HEAT TREATMENT, WELDING, Non-destructive testing- CRITICAL FLIGHT SAFETY INSPECTION) Suppliers were instructed to send in their certificates and parts, with on-site audits only if need arises

More on TelAve News

2) July 2002 Supplier Bulletin: AS9100 Certification must be ANSI–ANAB Accredited Suppliers were instructed to send in their certificates and parts, with on-site audits only if the need be.

Boeing's Confession on On-Site Supplier Audits

Boeing's procedures explicitly state: "Our preference is to deal with proven suppliers with excellent quality performance and not have to do on-site quality system surveys" (survey is no more than an audit). This is a confession that Boeing rarely stepped into supplier facilities unless necessary. For 22 years, Boeing relied on AS9100 or similar NADCAP certifications, accepting certificates and parts without on-site verification.

ATTENTION READER WHAT DOES: If Need Arises Or If Need Be means?

3) Boeing called ANSI–ANAB out on Supplier Portal or international equivalent (China, Iran, Pakistan equivalent to ANSI-ANAB ACCREDITATION)

4) ANSI–ANAB Website: Management System Accreditation Council (MSAC) (grant, suspend, or withdraw certification) Boeing sat as member on the MSAC webpage { How could Boeing grant, suspend and withdraw certification when they were not certified themselves?!

5) Boeing pursuing AS9100 certification now from ANSI–ANAB—the very body it mandated for suppliers July 2002 and sits on the Management System Accreditation Council (MSAC)—is a direct conflict of interest and a fraud. Leveraging international accreditation's under ILAC or IAF to validate decades of self-declared compliance is fraudulent. International Accreditation Forum incorporated in Delaware (ANSI -ANAB founded the IAF) IAF sister organization in Australia are associations of national and international accreditation bodies equivalent in accreditation to ANSI-ANAB who are also underwriters for IAF/ILAC meaning they are subjected legally to systematic and product failure responsibility for IAF and ILAC members.

Subject to oversight Boeing did not follow

Table 2 — Critical AS9100 Failures Leading to Aircraft Risk, Potential Crash

Table 3 — Boeing Quality Failures Timeline (2002–2024)

More on TelAve News

*** 2018-2019 MCAS system caused 2 fatal crashes Ethiopian and Indonesian flights killing 346 passengers.

Expert Findings by DARYL GUBERMAN

In October 2024, World recognized QA Expert and Boeing Shareholder DARYL GUBERMAN conducted an independent investigation across Boeing facilities in Washington State: Everett, Auburn, Renton, and Northfield. Employees were unaware of AS9100 standards and internal audit procedures, exposing a culture of compliance neglect. Elizabeth Lund, then VP of Quality, admitted in June 2024 that Boeing was only then "willing to obtain AS9100 certification"(after 22 years of Boeings neglect)—a tacit acknowledgment of decades of evasion.

Conclusion

Doug Ackerman's 35 years at Boeing, including his critical 2020–2024 Supplier Quality tenure, reveal systemic quality failures. His silence on the AS9100 gap, coupled with his position on the PRI/NADCAP board, underscores an era where certification was treated as paperwork rather than protection—placing passenger safety, supplier credibility, and aviation trust at significant risk.

While Doug Ackerman Oversaw the 777 Program: Quality Issues & Whistleblower Testimony

On April 17, 2024, whistleblower Sam Salehpour testified before the U.S. Senate regarding alarming quality problems on Boeing's 777 program, where Ackerman was involved from 2002–2022. Salehpour described forced-fit assemblies leaving structural gaps that could lead to midair failure, production shortcuts jeopardizing long-term airframe integrity, and systemic pressure to overlook defects in pursuit of production targets.World recognized QA Expert and Boeing Shareholder DARYL GUBERMAN attended the DHS Subcommittee Whistleblower Meeting concerning Boeing's deeply concerning quality practices https://www.newstribune.com/photos/2024/apr/18/3749044/.

Table 1 — Boeing's Conflict of Interest at a Glance

| Entity | Role | Conflict |

| Boeing | Non-AS9100 certified aerospace giant (2002–2024) | Sat on ANSI–ANAB MSAC with certification powers |

| ANSI–ANAB MSAC | Management System Accreditation Council managing AS9100 certifications | Listed Boeing as a council member that can grant, suspend and withdraw certification |

| Boeing Suppliers | Forced to obtain AS9100 via ANSI–ANAB accreditation | Unequal application of standards |

Reason Why:

A) Nineteen days after 911 Boeing came out with a notification to lay off 20,000 to 30,000 employees.

1) April 2002 Supplier Bulletin Performance Review Institute NADCAP National Aerospace and Defense Contractors Accreditation Program certification (HEAT TREATMENT, WELDING, Non-destructive testing- CRITICAL FLIGHT SAFETY INSPECTION) Suppliers were instructed to send in their certificates and parts, with on-site audits only if need arises

More on TelAve News

- Your Body Isn't Broken—It's Out of Balance: The New Book Revealing the Blueprint to Restore Hormone Balance, Sleep, Gut & Metabolic Health

- Youth Take the Lead: Kopp Foundation for Diabetes Hosts "By Youth, For Youth, With T1D" Gala on October 8 at Blue Bell Country Club

- Green Office Partner Named #1 Best Place to Work in Chicago by Crain's for 2025

- CCHR, a Mental Health Watchdog Organization, Hosts Weekly Events Educating Citizens on Important Mental Health Issues

- Netverse Could Diminish the Reliance on Cyber Security Software & Companies Through its AI, Patented App-less Technologies & Phinge Mobile Hardware

2) July 2002 Supplier Bulletin: AS9100 Certification must be ANSI–ANAB Accredited Suppliers were instructed to send in their certificates and parts, with on-site audits only if the need be.

Boeing's Confession on On-Site Supplier Audits

Boeing's procedures explicitly state: "Our preference is to deal with proven suppliers with excellent quality performance and not have to do on-site quality system surveys" (survey is no more than an audit). This is a confession that Boeing rarely stepped into supplier facilities unless necessary. For 22 years, Boeing relied on AS9100 or similar NADCAP certifications, accepting certificates and parts without on-site verification.

ATTENTION READER WHAT DOES: If Need Arises Or If Need Be means?

3) Boeing called ANSI–ANAB out on Supplier Portal or international equivalent (China, Iran, Pakistan equivalent to ANSI-ANAB ACCREDITATION)

4) ANSI–ANAB Website: Management System Accreditation Council (MSAC) (grant, suspend, or withdraw certification) Boeing sat as member on the MSAC webpage { How could Boeing grant, suspend and withdraw certification when they were not certified themselves?!

5) Boeing pursuing AS9100 certification now from ANSI–ANAB—the very body it mandated for suppliers July 2002 and sits on the Management System Accreditation Council (MSAC)—is a direct conflict of interest and a fraud. Leveraging international accreditation's under ILAC or IAF to validate decades of self-declared compliance is fraudulent. International Accreditation Forum incorporated in Delaware (ANSI -ANAB founded the IAF) IAF sister organization in Australia are associations of national and international accreditation bodies equivalent in accreditation to ANSI-ANAB who are also underwriters for IAF/ILAC meaning they are subjected legally to systematic and product failure responsibility for IAF and ILAC members.

Subject to oversight Boeing did not follow

Table 2 — Critical AS9100 Failures Leading to Aircraft Risk, Potential Crash

| AS9100 Clause | Requirement | Boeing's Failure | Potential Aircraft Risk |

| 7.1.5 Monitoring & Measurement Resources | Calibrate tools for precision manufacturing. | Relied solely on supplier paperwork without independent verification. | Fatigue-critical components may fail mid-flight. |

| 8.4.2 Control of External Providers | Mandates supplier oversight and audits. | Accepted certificates without on-site inspection. | Components of unknown origin or improper heat treatment. |

| 8.5.1 Control of Production & Service Provision | Enforce welding, heat treatment, and NDT processes. | Failed to validate special process compliance (e.g., NADCAP). | Weld or material failure in critical systems. |

| 9.2 Internal Audit | Conduct routine internal audits. | Audits non-existent or unrecognized by employees. | Defects remain undetected, escalating fleet-wide. |

| 10.2 Nonconformity & Corrective Action | Identify and fix defects systematically. | No certified QMS to enforce corrections. | Latent flaws may result in catastrophic incidents. |

Table 3 — Boeing Quality Failures Timeline (2002–2024)

More on TelAve News

- "Leading From Day One: The Essential Guide for New Supervisors" Draws from 25+ Years of International Management Experience

- New Slotozilla Project Explores What Happens When the World Goes Silent

- The Two Faces of Charles D. Braun: How the Novel, Posthumously Yours, Came to Life

- Counseling Center of New Smyrna Beach Expands Affordable Mental Health Services for Volusia County

- Athena Forge (ATFG) Introduces Advanced Token for Technology-Driven Financial Ecosystem

| Issue / Time Period | Details | Potential Risk to Aircraft |

| 2002 (Suppler NADCAP) (Supplier AS9100)- | Boeing demanded certification from suppliers despite not holding it itself. | Risk of uncertified parts entering production. |

| 2009 (ODA Adoption) Began 2005 Important*** | Boeing began self-certifying under FAA's ODA program. By 2018 Boeing was certifying 96% of its own work. | Reduced external oversight of design and safety certifications. |

| 2020–Present (Ackerman) | Ackerman oversaw Supplier Quality; on-site audits were minimized. | Increased reliance on paperwork, potential for errors or substandard parts. |

| 2022–Present (PRI Board) | Ackerman joined PRI's board overseeing NADCAP standards. | Overlap of Boeing management and certification processes. |

| June 2024 (Certification) | Boeing finally is willing to obtained AS9100 certification after 22 years. Elizabeth Lund VP June 2024 (Retired December 2024) | Indicates long-term internal non-compliance with supplier expectations. |

*** 2018-2019 MCAS system caused 2 fatal crashes Ethiopian and Indonesian flights killing 346 passengers.

Expert Findings by DARYL GUBERMAN

In October 2024, World recognized QA Expert and Boeing Shareholder DARYL GUBERMAN conducted an independent investigation across Boeing facilities in Washington State: Everett, Auburn, Renton, and Northfield. Employees were unaware of AS9100 standards and internal audit procedures, exposing a culture of compliance neglect. Elizabeth Lund, then VP of Quality, admitted in June 2024 that Boeing was only then "willing to obtain AS9100 certification"(after 22 years of Boeings neglect)—a tacit acknowledgment of decades of evasion.

Conclusion

Doug Ackerman's 35 years at Boeing, including his critical 2020–2024 Supplier Quality tenure, reveal systemic quality failures. His silence on the AS9100 gap, coupled with his position on the PRI/NADCAP board, underscores an era where certification was treated as paperwork rather than protection—placing passenger safety, supplier credibility, and aviation trust at significant risk.

Source: GUBERMAN-PMC,LLC

0 Comments

Latest on TelAve News

- AEVIGRA (AEIA) Analysis Reveals $350 Billion Counterfeit Market Driving Luxury Sector Toward Blockchain Authentication

- Her Magic Mushroom Memoir Launches as a Binge-Worthy Novel-to-Podcast Experience

- NetverseAI By Phinge to Bring Verified Search Results to the Netverse Patented App-less Platform to Solve the ills of Todays AI & Search Engines

- Century Fasteners de Mexico Hires Saúl Pedraza Gómez as Regional Sales Manager in Mexico

- Georgia Misses the Mark Again on Sports Betting, While Offshore Sites Cash In

- $40 Price Target for $NRXP in H. C. Wainright Analyst Report on Leader in $3 Billion Suicidal Depression Market with Superior NRX 100 Drug Therapy

- Nashville International Chopin Piano Competition Partners with Crimson Global Academy to Support Excellence in Education

- Phinge Asked Google AI, How Could Netverse Disrupt Crypto Like Bitcoin? Its Answer Might Shock You

- AHRFD Releases Market Analysis: Cryptocurrency Market's Institutional Transformation Accelerating

- Ubleu Crypto Group Analyzes European Digital Asset Market Opportunities Amid Regulatory Evolution

- NIUFO Examines European MiCA Regulation's Impact on Digital Asset Trading Markets

- Wzzph Analyzes Crypto Market Maturation as Institutional Capital Drives $50B ETF Inflows

- GXCYPX Analyzes South America's Emerging Digital Asset Market Dynamics

- Keyanb Crypto Exchange Positions for Latin America's $600 Billion Remittance Opportunity Amid Global Regulatory Shifts

- NAQSN Analysis: $2.75 Trillion Digital Asset Market Demands Unified Infrastructure

- Trinity Accounting Practice Celebrates 22 Years Serving Beverly Hills Businesses

- YuanziCoin Unveils Revolutionary Shariah-Compliant Blockchain Architecture for 1.8 Billion Muslims Worldwide

- AGEIMMUNE Launches Brilliant D3 + Magnesium & K2: A Doctor-Formulated Supplement for Bone, Immune & Heart Health Support

- YMCA of the Jersey Shore Helps Residents Take Control of Health

- Z-CoiL Footwear, Albuquerque's Original Spring Shoe, Steps Into ABC's Shark Tank Season Premiere