Popular on TelAve

- Voices Rising Festival Celebrates Diversity in E. Islip, GRAMMY Governor LACHI performs!

- Dr. Stephen Shainbart, PHD, Highlights 5 Reasons to Discuss Family Therapy and Couples Counseling in Buffalo, NY

- Origination of Prince Oak's new alias and reasons of his change — the Eurasian Prince's newest nominal label is "Papa Eurasia"

- New Study Reveals Alarming Cardiac Risks Associated with Electroshock Treatment

- U.S. Beauty and Personal Care Market Booming with Rising Demand for Natural and Organic Products

- Tim O'Loughlin Appointed Chief Executive Officer of Vantiva and Co-opted as a Director of the Board

- Situ Ve Offers a New Perspective on Love Amid the Rising Passport Bro Movement

- BroadSource and Access4 Introduce UCPayd, a Game-Changing Communication Security Solution

- Bridge Cable Partners With Alarm.com To Expand Security Solutions

- Superior Thin Film Solar Panel Advancements Open Great Opportunities in the Rapidly Developing Aerospace and Related Sectors: Stock Symbol: ASTI

Similar on TelAve

- From Tax Advisor to Community Advocate

- WYSIWYG Marketing Welcomes Ellen McColl as Director of Business Development

- Inc. Names BYLTup as a 2024 Power Partner Award Winner

- Bainbridge Custom Builders Launches to Redefine Custom Construction and Renovation in Philadelphia

- 76 FENCE Expands in North Carolina with Strategic Franchise Growth Led by Regional Developer Drew Myers

- X3 Build Shares 4 Essential Questions to Ask a Custom Home Builder in Santa Monica Before Hiring Them

- LCC Asia Pacific Celebrates Milestone with 550th Edition of Engineering & Industrial Services Sector Weekly Research Report

- Brooklyn Artist Allison Eden Studios Creates Presidential Portraits For Auction To Predict Election Results

- 5 Questions to Always Ask Roofing Companies in Memphis Before Hiring Them

- Expert HVAC Upgrade Tips to Maximize Energy Efficiency

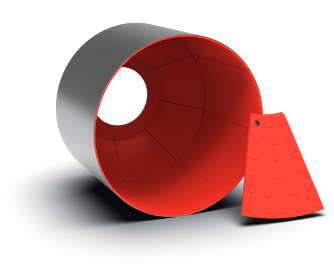

Enhance Your Concrete Plant Equipment Durability with Urethane Liners, Wear Parts and Regular Maintenance

TelAve News/10844636

LUCK, Wis. - TelAve -- Urethane Liners 101

Urethane liners are more durable and longer lasting than traditional steel liners. Their inherent flexibility helps absorb impact, reducing wear and minimizing the risk of cracking or breaking. In addition to their durability, urethane liners also offer a quieter operation by reducing noise levels in cement blending processes. This not only protects the equipment but also creates a safer and more pleasant working environment for employees. Some urethane solutions are customizable to fit various equipment types, ensuring seamless integration and optimal protection.

Tailored Solutions for Concrete Equipment

Urethane wear parts are designed to address the specific challenges faced by concrete plants and equipment. Whether you're operating a batch plant, continuous mixer, or any other type of cement blending system, these wear parts provide protection in high-wear areas, helping to reduce the need for frequent repairs. Custom-fabricated to match your equipment specifications, wear parts deliver maximum performance and durability, even in the most demanding applications.

In addition to their protective qualities, urethane liners and wear parts promote better material flow. By preventing material build-up and promoting smooth movement, urethane components can improve efficiency and reduce energy consumption in your concrete blending operations. The non-stick properties of urethane help prevent cement from adhering to surfaces, ensuring smoother operation and reducing the frequency of cleaning.

More on TelAve News

The Importance of Regular Maintenance

While urethane liners and wear parts significantly improve the durability of cement blending equipment, regular maintenance is still essential to ensure optimal performance. Routine inspections should be conducted to check for signs of wear, such as thinning or damage to the liners. Replacing worn parts promptly will prevent further damage to the equipment and minimize downtime and by establishing a consistent maintenance schedule, you can identify and address issues before they escalate into costly repairs or replacements.

Best Practices for Cleaning Cement Blending Equipment

Cleaning cement blending equipment is vital to preventing build-up and maintaining efficiency. Regularly removing accumulated cement, sand, and other materials from hoppers, chutes, and mixers ensures smooth operation and reduces wear on urethane liners and wear parts. High-pressure water or air can be used to remove debris, but care should be taken to avoid damaging the liners.

For stubborn build-up, using specialized cleaning tools designed for concrete equipment can help remove hardened material without harming the urethane components. It's essential to clean hard-to-reach areas, such as corners and seams, to prevent the build-up of material that could compromise equipment performance over time. Additionally, using cleaning agents that are safe for urethane materials will ensure that your liners and wear parts remain in good condition after each cleaning cycle.

More on TelAve News

Not All Urethane Liners Are the Same

In the concrete production industry, equipment endures constant exposure to abrasive materials such as sand, gravel, and cement, which can lead to premature wear and tear. Yet you can count on high quality reliable liners to extend the lifespan of your equipment, reduce maintenance costs, and improve overall operational efficiency.

However, keep in mind not all urethane liners and wear parts will perform as promised and why it is essential to choose a high-quality manufacturer of urethane liners such as Durex Products to ensure maximum durability and protection against abrasive materials.

About Durex Products

Durex's urethane concrete liners and wear parts are specifically designed for concrete plants and equipment to withstand the harsh conditions of concrete production. Durex liners are particularly effective in protecting areas prone to high impact and wear, such as hoppers, chutes, and mixing drums and are customizable to fit various equipment types, ensuring seamless integration and optimal protection.

In conclusion, investing in Durex Products' urethane concrete liners and wear parts is a smart choice for any concrete plant or equipment operator looking to improve durability and performance. With proper maintenance and cleaning practices, these urethane solutions are designed to extend your equipment's lifespan, lower operational costs, and ensure peak production efficiency. To learn more about our products visit: https://durexproducts.com

Urethane liners are more durable and longer lasting than traditional steel liners. Their inherent flexibility helps absorb impact, reducing wear and minimizing the risk of cracking or breaking. In addition to their durability, urethane liners also offer a quieter operation by reducing noise levels in cement blending processes. This not only protects the equipment but also creates a safer and more pleasant working environment for employees. Some urethane solutions are customizable to fit various equipment types, ensuring seamless integration and optimal protection.

Tailored Solutions for Concrete Equipment

Urethane wear parts are designed to address the specific challenges faced by concrete plants and equipment. Whether you're operating a batch plant, continuous mixer, or any other type of cement blending system, these wear parts provide protection in high-wear areas, helping to reduce the need for frequent repairs. Custom-fabricated to match your equipment specifications, wear parts deliver maximum performance and durability, even in the most demanding applications.

In addition to their protective qualities, urethane liners and wear parts promote better material flow. By preventing material build-up and promoting smooth movement, urethane components can improve efficiency and reduce energy consumption in your concrete blending operations. The non-stick properties of urethane help prevent cement from adhering to surfaces, ensuring smoother operation and reducing the frequency of cleaning.

More on TelAve News

- Anaptyx Recognized as First in Customer Service

- The United States Environmental Protection Agency (USEPA) is SEBAC's 2024 Award for Excellence winner

- Author Riley G. Staliger Offers Tools to Escape Guilt-Driven Relationships AKA Obligationships Using Pop Culture

- Healthcare Consulting Firm, Coker, Announces Acquisition of NorthGauge Healthcare Advisors

- Kaplan Morrell Named Exclusive Workers' Compensation Firm for Greeley Fire Fighters

The Importance of Regular Maintenance

While urethane liners and wear parts significantly improve the durability of cement blending equipment, regular maintenance is still essential to ensure optimal performance. Routine inspections should be conducted to check for signs of wear, such as thinning or damage to the liners. Replacing worn parts promptly will prevent further damage to the equipment and minimize downtime and by establishing a consistent maintenance schedule, you can identify and address issues before they escalate into costly repairs or replacements.

Best Practices for Cleaning Cement Blending Equipment

Cleaning cement blending equipment is vital to preventing build-up and maintaining efficiency. Regularly removing accumulated cement, sand, and other materials from hoppers, chutes, and mixers ensures smooth operation and reduces wear on urethane liners and wear parts. High-pressure water or air can be used to remove debris, but care should be taken to avoid damaging the liners.

For stubborn build-up, using specialized cleaning tools designed for concrete equipment can help remove hardened material without harming the urethane components. It's essential to clean hard-to-reach areas, such as corners and seams, to prevent the build-up of material that could compromise equipment performance over time. Additionally, using cleaning agents that are safe for urethane materials will ensure that your liners and wear parts remain in good condition after each cleaning cycle.

More on TelAve News

- Drive for Gratitude Significantly Impacts Veterans Well-being

- The Voice of the Wooden Dragon is Latest Release from NFB Publishing

- AONE Fest 2024: Celebrating Creativity and Community at Red Dot Studios

- At Your Service Plumbing Honored with Silver Award in The Best of Pierce County

- Retired Navy SEAL Launches Barrett Strategic Leadership Group (BSLG)

Not All Urethane Liners Are the Same

In the concrete production industry, equipment endures constant exposure to abrasive materials such as sand, gravel, and cement, which can lead to premature wear and tear. Yet you can count on high quality reliable liners to extend the lifespan of your equipment, reduce maintenance costs, and improve overall operational efficiency.

However, keep in mind not all urethane liners and wear parts will perform as promised and why it is essential to choose a high-quality manufacturer of urethane liners such as Durex Products to ensure maximum durability and protection against abrasive materials.

About Durex Products

Durex's urethane concrete liners and wear parts are specifically designed for concrete plants and equipment to withstand the harsh conditions of concrete production. Durex liners are particularly effective in protecting areas prone to high impact and wear, such as hoppers, chutes, and mixing drums and are customizable to fit various equipment types, ensuring seamless integration and optimal protection.

In conclusion, investing in Durex Products' urethane concrete liners and wear parts is a smart choice for any concrete plant or equipment operator looking to improve durability and performance. With proper maintenance and cleaning practices, these urethane solutions are designed to extend your equipment's lifespan, lower operational costs, and ensure peak production efficiency. To learn more about our products visit: https://durexproducts.com

Source: Durex Products

0 Comments

Latest on TelAve News

- Arbutus Medical Launches Digit Revision SwiftKit™ to Streamline Trauma Care and Improve Emergency Department Throughput

- MarketTecNexus CEO's Digital Clone Introduces "AI Business Scale Up™," Services Redefining AI Transformation for Mid-Size Businesses

- Los Defensores Champions Underserved Communities with the Launch of "Siempre Contigo" Initiative in Houston

- Natural Sweetener Health Trend on the Rise: Black Friday Special Discounts Are Here!

- TOKYO SKYTREE® is Now Selling Premium Traditional Performing Arts Experiences

- Vantiva and e& Deploy First eSIM-enabled 5G Fixed Wireless Access Gateway for United Arab Emirates Subscribers

- OpsVeda Announces General Availability Of Release 10.0 Of Its AI Powered Operations Command Center

- Celebrate Christmas 2024 with Exclusive Deals and Festive Offers

- Klatt Works, Executive Flightways, L2 Aviation, and Ametek Revolutionize Business Jet Safety with the First SAVED System STC for the G550

- Bainbridge Custom Builders Launches to Redefine Custom Construction and Renovation in Philadelphia

- 76 FENCE Expands in North Carolina with Strategic Franchise Growth Led by Regional Developer Drew Myers

- See Our Earth Champions Environmental Education and Conservation Through Initiatives, Dad Hats and Mountain Hats

- NEW AI Launch! StarboxAI VI-Pro - Live Streaming System; Empowering 800 Merchants to Boost Sales to Over 2 Million Users: StarBox (Stock Symbol: STBX)

- El Ranchito Appoints New President

- Mrs Elemental® USA National Competition Introduces the Prestigious Panel of National Judges

- "House of War" Live Event & Podcast Series by Daniel Sadan Debuts This Week

- Balam and Transfera Unveil the World's First Remittance-as-a-Service Platform

- AI-driven money-saving tips: Black Friday shopping guide for 2024

- myStaze: Revolutionizing Live Music Streaming in the U.S. – Artists Earn 90% of Ticket Sales!

- Crosby Tatum's "The People, United" heads to Georgia & New York City during 2024 US General Election Season